durability and will last for the life of your building.

Ordering Hotline

(303) 455-5133

We use the finest virgin High Density Polyethylene (HDPE) for consistency and structural integrity.

We are a green company and support the recycling of plastics whenever possible. Our remainder plastics are reground and put back in to our resin and reused for certain products such as our stackable rebar/panel chair.

We use the state of the art TRUMP CNC milling machine to produce all our molds and the REED plastic ejection molding machine to produce all our products.

The TRUMP CNC machine produces detailed and precise prehardend steel, aluminum and beryllium-copper alloy molds with a lifespan to produce thousands and thousands of products. The REED molding machine is a workhorse that can produce hundreds of products per minute, with the highest quality and precise composition for the greatest structural integrity.

All of our products will last the lifetime of your project

All of our products are specifically designed to support precast concrete solutions for entire buildings, including floors, walls, stairs and elevator shafts. Speed of construction and incredible durability, precast constructed buildings are engineered to last for generations to come.

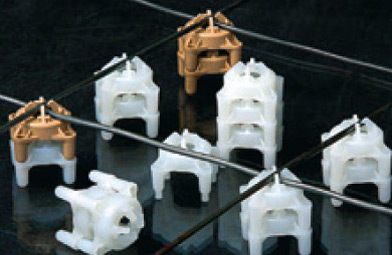

Precast form ready for concrete pour

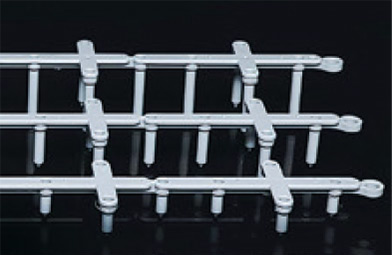

Precast concrete form, photo courtesy of Prestress Concrete in Newton Kansas. Craig’s Construction Specialties standard mesh chairs are used to hold the wire mesh at the designated height during the concrete the curing process.